The 5 Most Common Types of 3D Printing, and When to Use Them

3D printing or Rapid Prototyping

is a cutting-edge manufacturing process that's shaking up industries everywhere. It constructs various types of objects layer upon layer, following digital blueprints. This innovative technology is having a huge impact on fields ranging from medicine to engineering, revolutionizing traditional manufacturing methods.

Let's dive into the top five 3D printing types, with a special focus on methods like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Multicolor 3D Printing, since these are what we specialize in.

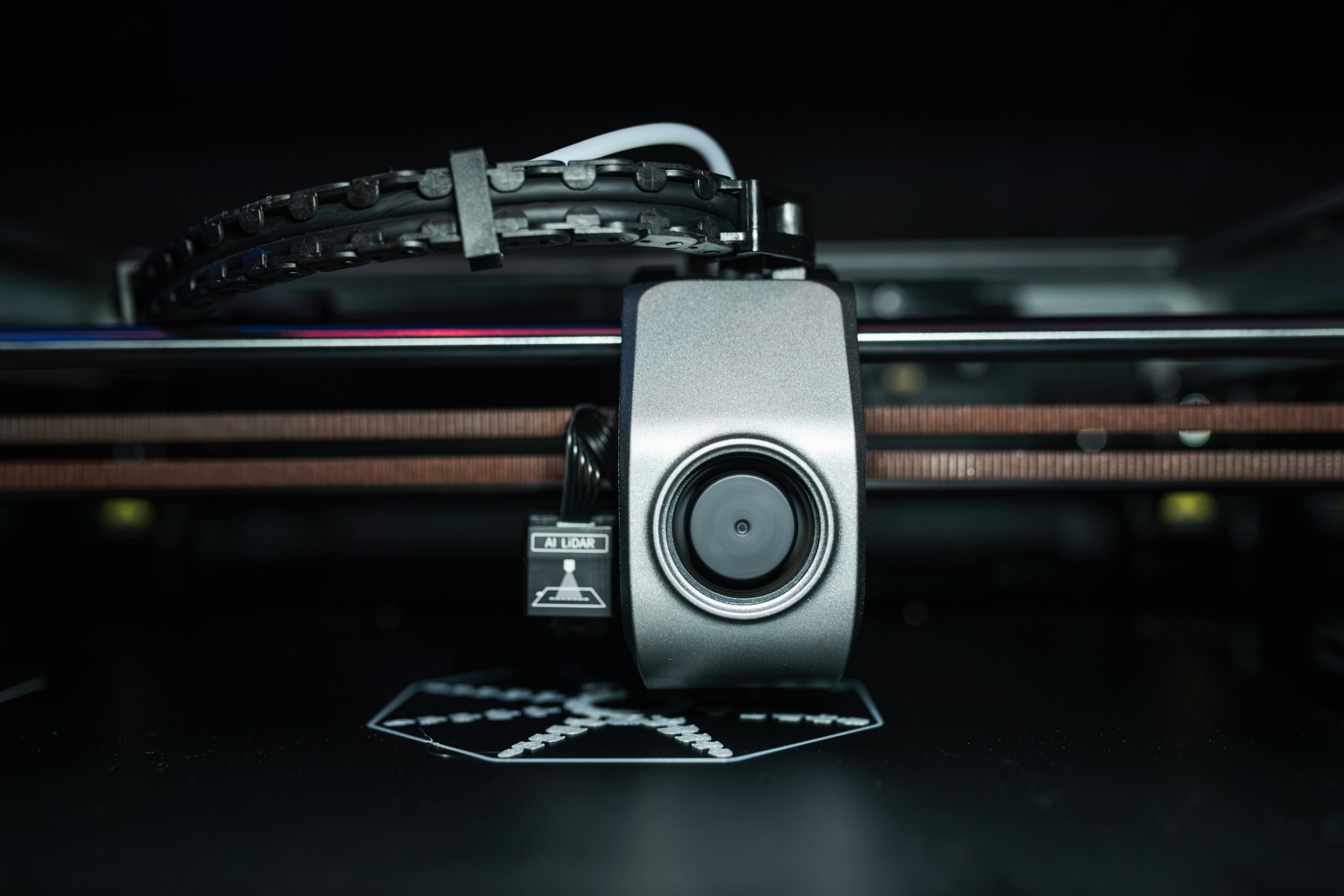

Fused Deposition Modeling (FDM) 3D Printing

Fused Deposition Modeling (FDM) is a modern way to make things layer by layer using melted material. It's like building with tiny, precise threads of melted plastic. This method is efficient and uses special plastic filaments to create solid objects.

Benefits:

Fused Deposition Modeling (FDM) is cost-effective because it uses cheap thermoplastics, making it budget-friendly for different purposes. These materials are also durable, so FDM parts are strong and reliable for real-world use. FDM is great for quickly making functional prototypes, especially when a super smooth finish isn't needed, making it perfect for fast prototyping and design improvements.

Drawbacks:

Fused Deposition Modeling (FDM) printing has its downsides to keep in mind. First off, it tends to be slower, especially when you're printing bigger or more complicated objects. So, if you're on a tight schedule, it might not be the best option. In addition, because FDM builds things layer by layer, the finished product can end up with a rougher surface compared to other 3D printing methods. That might not matter for every project, but it's worth considering if you're aiming for a really smooth finish. Despite these quirks, FDM still brings a lot to the table and can work wonders in many situations.

Best uses:

FDM printing has its perks, as it's great for making low cost prototypes because you can see how your designs look and work before making a final product. It's also a great option for making jigs, fixtures, or production parts where the surface finish is unimportant, or where function or aesthetics could actually be improved by a rough surface finish.

Stereolithography (SLA) / Resin 3D Printing

Stereolithography (SLA), also called resin printing, uses either a laser or a UV projection screen to harden liquid resin into solid plastic. The light source traces a pattern on the liquid resin's surface, solidifying it layer by layer to create the final object.

Benefits:

SLA prints faster than many other 3D printing methods. It produces parts with smooth, high-quality surface finishes that are perfect for detailed and intricate designs. The parts are also tough and durable, making SLA suitable for both prototypes and final products.

Drawbacks:

SLA 3D printing can be more expensive due to the cost of materials and the production process. It also involves hazardous materials that need careful handling and proper disposal.

Best uses:

Stereolithography 3D printing is great for prototyping when you need high detail and smooth finishes. It's also excellent for making parts that need to be as good as those produced by injection molding.

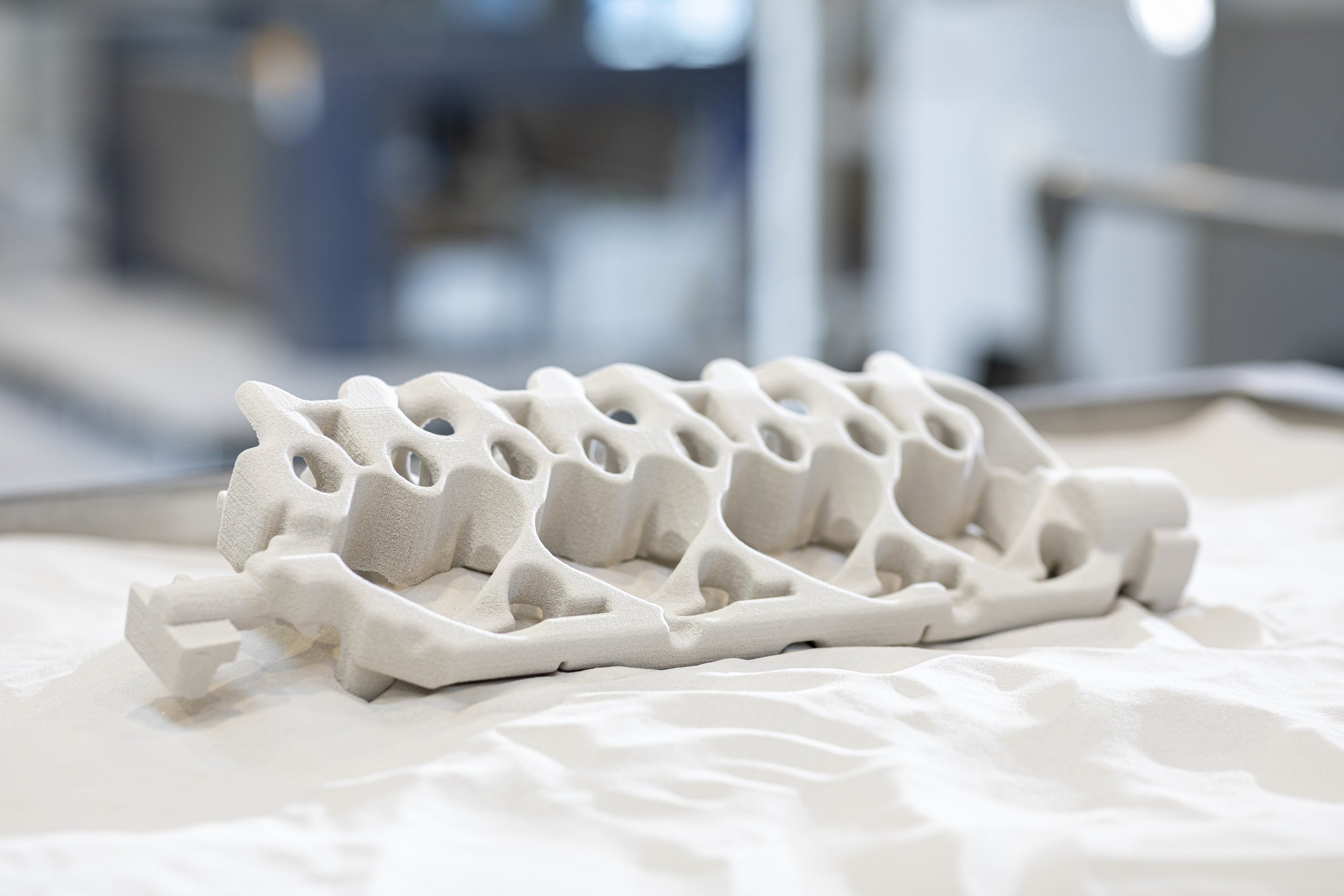

Selective Laser Sintering (SLS) 3D Printing

Selective Laser Sintering (SLS) is an advanced 3D printing technique employing a laser to meld powdered materials such as nylon into sturdy structures. The laser moves across the powder according to sections from a 3D digital model.

Benefits:

SLS creates strong, durable parts that can handle significant stress and wear. It doesn't need support structures because the surrounding powder supports the parts during printing. This makes it excellent for producing complex geometries that are hard to achieve with other methods. While SLS is impressive, I believe SLA is one of the best technologies available. SLA is faster, produces beautiful surface finishes, and the prints can be very tough depending on the material.

Drawbacks:

SLS can be costly due to the price of materials and the complexity of the machinery. Additionally, the surface finish of SLS parts is usually rougher compared to those made with SLA.

Best uses:

SLS is perfect for creating functional parts with intricate designs. It's also great for prototyping and production when part strength and durability are essential, or for when one wants to 3D print in metal instead of plastic.

Binder Jetting 3D Printing

Binder Jetting is a method in 3D printing where a liquid binding agent is applied onto a bed of powder, bonding the material together layer by layer. The object is built up from the powder bed, with the binder holding the particles together to form the final structure.

Benefits:

Binder Jetting stands out because it can produce full-color prints, which is rare among 3D printing technologies. Since the process doesn’t involve heat, it greatly reduces the risk of warping, a common problem in other 3D printing methods. It's also great for large-scale production, allowing for the efficient creation of multiple parts at once.

Drawbacks:

Binder Jetting parts might not be very strong unless they go through extra steps after printing. These extra steps, like infiltration, take more time and money but make the parts stronger and more durable. They are often still not as durable as SLA or FDM parts, even after this process.

Best uses:

Binder Jetting is fantastic for prototyping and multicolor 3D printing, as it allows for creating full-color models and detailed parts. It's also perfect for producing large batches of parts, making it a good choice for manufacturing environments that need volume production in full color.

Multicolor 3D Printing

Multicolor 3D printing enables the creation of objects using a variety of colors, with some printers accommodating up to 16 different colors. This method offers intricate detailing and a diverse range of colors in the final output.

Benefits:

Printing in multiple colors makes this technique suitable for both artistic and practical purposes. It enhances the visual appeal and functionality of prototypes and final products by allowing for color variation and intricate designs.

Drawbacks:

Multicolor 3D printing necessitates a more intricate setup and maintenance compared to single-color printing. Additionally, the cost of materials may be higher, potentially impacting the overall printing expenses.

Best uses:

Multi-color 3D print technology is well-suited for prototyping projects where color differentiation is essential. It's also beneficial for producing final products requiring multiple colors, adding both aesthetic appeal and functional value to the end result.

Choosing the Perfect 3D Printing Method

for Your Project

The types of 3D printers offer a myriad of avenues to breathe life into your visions. Selecting the proper 3D printing method relies on your unique needs and goals. Whether you're testing a new design or creating finished products, the method you choose can have a big impact on the result.

Here at the Industrial Engraving and Manufacturing Company, we specialize in FDM, SLA, and Multicolor 3D printing. If you're prepared to transform your ideas into tangible reality, don't hesitate to reach out to us for a quote. Let's work together to bring your vision to life!

Photo attributions:

Image by <a href="https://www.freepik.com/free-photo/lifestyle-designer-using-3d-printer_96363632.htm#query=3d%20printer&position=1&from_view=keyword&track=ais_user&uuid=23ad4d28-f58b-4f95-a656-8db11029a54f">Freepik</a>

<a href="https://www.freepik.com/free-photo/lifestyle-designer-using-3d-printer_96363579.htm#fromView=search&page=1&position=6&uuid=ff912911-999d-44ae-a282-55e3dfe5f4d2">Image by freepik</a>

https://www.flickr.com/photos/fdecomite/14272917927